What is Factory 4.0?

The industry is going through the 4th industrial revolution, so we are talking about industry 4.0. Let us look at the great periods that have passed through this one, to move from mechanical production to digital transformation at the heart of today’s and tomorrow’s exchanges.

1st Industrial Revolution: Mechanical Production

At the heart of the first industrial revolution was coal. At that time it was realized that he could provide energy in large quantities to power James Watt’s famous steam engine. Introduced to factories in 1760, it revolutionized the metallurgical sector. Steel allows the building of new bridges. The railway is expanding at an unprecedented rate.

The steam engine will allow ships to be propelled first on rivers as early as 1780. From 1820, connections across the Channel and even across the Atlantic were provided by the steam engine on larger and larger buildings. In 1815, on Earth, the first steam locomotive was patented.

2nd Industrial Revolution: Mass production

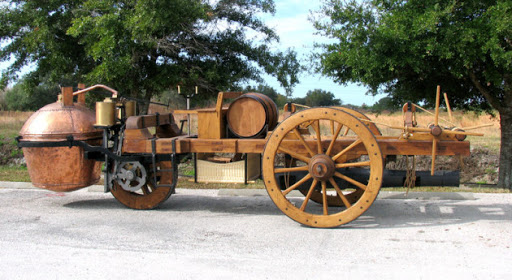

From 1870, the first steam cars appeared. The problem is that the engine is very large and still provides too little power. For example, the “steam-hot” provided enough energy to travel at 4km/h.

But the discovery of oil will allow the creation of the first automobile equipped with an explosion engine, the “Patent-Motorwagen”. With a capacity of up to 15km/h, this technological revolution will pave the way for a new era: mass production.

The use of the alternating current allowed by N.Tesla as early as 1888 will transform the landscape of the industry that will now be organized around large multinational firms.

The end of the Second Industrial Revolution was at the beginning of the First World War. It was during this period that the appearance of the mythical Ford T appeared as well as the work at the chain.

The 3rd Industrial Revolution: The Sustainable Economy

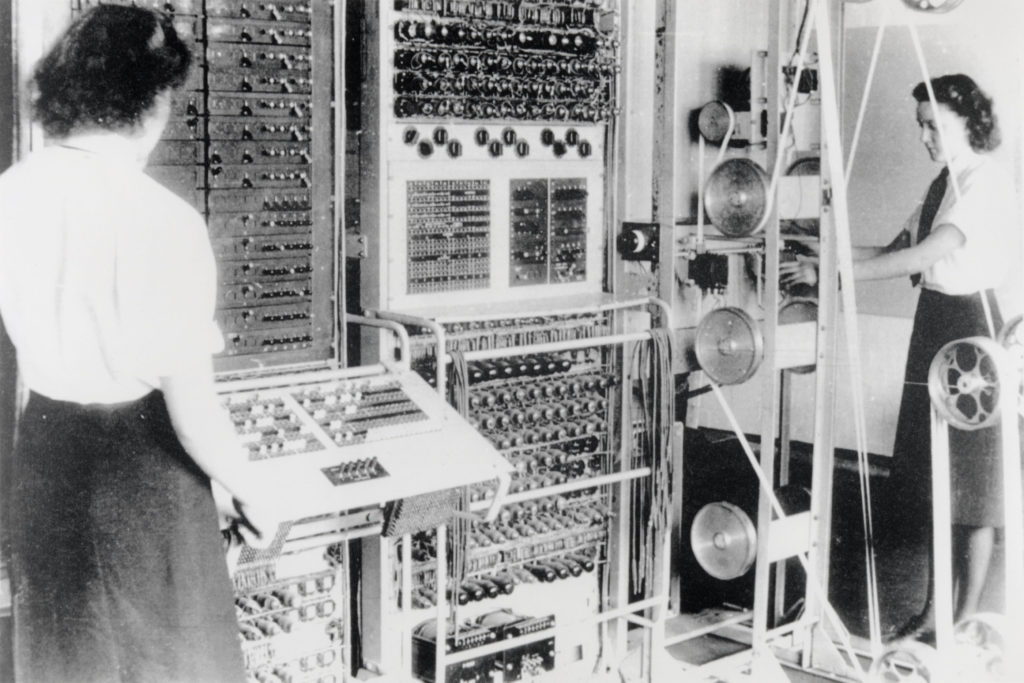

Between the creation of the first computer, the colossus (1943) and the transition to a sustainable economy, more than half a century passed. The term was introduced by Jeremy Rifkin at the end of the 20th century. The idea was born in the 70s, this revolution was thought as a solution. Indeed, in response to nuclear accidents (Chernobyl, Fukushima), ecological disasters and oil-related problems, Industry 3.0 wants to be sustainable. Mass consumption and the planet’s limited resources are at the heart of the problem. The development of a sustainable economy is made possible by the introduction of technology into the industry and its ultra-connection.

The third industrial revolution therefore relies mainly on the introduction of renewable energy. Fossil fuels that can be highly polluting depend on a distribution network with centralized production centres. All this leads to energy losses through its transport. An energy that is difficult to store.

The solution that this third revolution brings is to decentralize the places of production avoiding nuclear accidents but above all energy losses. Renewable energy is a climate-dependent energy. But their strong point is that they are complementary. Not enough wind power? Count on the solar panels. Not enough solar? Count on hydraulic energy, and so on. Today clean energy has to deal with the huge lobbying of oil, but they have already proved to us that it is possible to operate with 100%. For example, in Costa Rica, where almost all electricity has come from renewable energy since 2015.

Factory 4.0: The Digital Transition

The 4th industrial revolution will take place in the heart of the industry. Although it is newer than the third, it will take place in parallel. The challenge of the digital transition is in particular the convergence ot / IT. We invite you to read the article on OT/IT convergence by clicking here.

Factory 4.0 will be ultra-connected. Equipped with sensors, the equipment will all be interconnected, allowing access to dozens of information related to the management or maintenance of the machines. Predictive maintenance is also at the heart of the issues.

That’s the challenge UDS Atom faces. This software gives you access to the following features: ultra-sharp production line control, predictive maintenance, alarms, energy savings… Find out by clicking here.